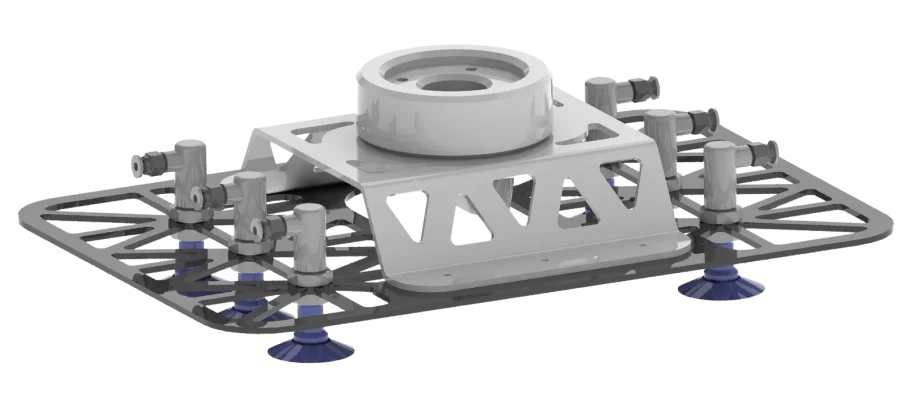

TR1: Mobile, Modular and Configurable Collaborative Robotic Cell

Modular, flexible and mobile todrobot robotic island. Extreme precision of welding execution, palletizing, deburring and more.

Modular, flexible and mobile todrobot robotic island. Extreme precision of welding execution, palletizing, deburring and more.

The robot is able to work around the clock, extremely simple to set up

Built to ensure long life and high performance with reduced recharge times

Small size and high adaptability help optimize internal logistics

Simplified maintenance thanks to quick battery replacement

La flessibilità di un braccio robotico, la mobilità di un robot autonomo e le caratteristiche di intelligenza artificiale e apprendimento automatico.

Todrobot rappresenta la soluzione ideale per l’automazione dei processi, sia per lotti di piccole e medie dimensioni, che per situazioni in cui la configurazione cambia costantemente.

Grazie alla sua rapida attivazione e al suo intuitivo sistema di comando, la cella robotica flessibile todrobot offre un accesso semplice all’automazione.

Sia che si tratti di montaggio, operazioni di pick-and-place o scopi di formazione, todrobot ti assiste precisamente dove ne hai più bisogno.

Hai la possibilità di scegliere tra una vasta gamma di accessori per creare un pacchetto personalizzato in base alle vostre specifiche esigenze.

Il TR1 è un robot progettato per lavorare insieme al personale umano, posizionandosi con precisione millimetrica rispetto agli oggetti. Riduce gli errori e le decisioni sbagliate, garantendo un flusso di produzione automatizzato e continuo.

The robot is able to work around the clock, extremely simple to set up

Built to ensure long life and high performance with reduced recharge times

Small size and high adaptability help optimize internal logistics

Simplified maintenance thanks to quick battery replacement

With a wide selection of accessories available and the freedom to customize the machine, you will be able to respond to the specific needs of the use case.

Thanks to its variable configurability and fast retooling times, you will be able to enjoy maximum flexibility in your processes and fully exploit the potential for modernizing your production.

Possibility to easily integrate additional components into the workbench of the flexible robotic island, based on specific wishes and needs.

Reduction of times and errors in order processing which leads to work efficiency and cost reduction.

By replacing the tools you can adapt the system to your production process. It can carry out picking & place from shelves and workstations by reprogramming it according to future needs.

It does not require structural modifications and masonry works of the warehouse. Adaptable to future changes in the warehouse working area.

Just like an operating system, it allows the installation of multiple elements that make it capable of satisfying multiple operational needs. The TR1 robotic island serves as the basic operating system for the different needs it can be used for.

The composition operations of the TR1 are Plug&Play, that is, simple, immediate and immediately functional!